When it comes to flooring solutions that offer durability, style, and safety, the epoxy quartz system stands out as a top choice. Popular in commercial, industrial, and even residential spaces, this flooring system combines the resilience of epoxy with the beauty of quartz aggregate, creating a surface that is both functional and visually appealing.

What is an Epoxy Quartz System?

An epoxy quartz system is a seamless flooring solution made by combining colored quartz granules with high-performance epoxy resins. The quartz aggregate is broadcast into the epoxy base coat and then sealed with multiple layers of epoxy or polyurethane, creating a tough, slip-resistant surface.

This system is well-known for its long-lasting strength, chemical resistance, and customizable aesthetics, making it ideal for high-traffic areas.

Key Benefits of Epoxy Quartz Flooring

1. Exceptional Durability

Epoxy quartz flooring is built to withstand heavy foot traffic, machinery, and daily wear and tear. Unlike traditional floors, it won’t crack, chip, or peel easily.

2. Slip Resistance & Safety

Because quartz granules are integrated into the surface, these floors are naturally slip-resistant. This makes them perfect for areas where spills, moisture, or safety are a concern—such as hospitals, schools, restaurants, and laboratories.

3. Chemical & Stain Resistance

The epoxy quartz system is resistant to chemicals, oils, stains, and abrasions, which makes it a go-to flooring choice for industrial plants, food processing facilities, and commercial kitchens.

4. Customizable Designs

Quartz granules come in a wide range of colors and blends. Whether you want a subtle, professional look or a bold, decorative finish, epoxy quartz systems can be tailored to fit your design preferences.

5. Seamless & Hygienic Surface

The seamless installation leaves no joints or grout lines, which means dirt, bacteria, and spills can’t penetrate the surface. This makes cleaning easy and maintains a sanitary environment—perfect for medical facilities and food production areas.

6. UV and Impact Resistant

High-quality epoxy quartz floors maintain their shine and color even under UV exposure and can handle heavy impacts without losing performance.

Where is Epoxy Quartz Flooring Used?

The epoxy quartz system is versatile and suitable for multiple industries, including:

- Healthcare Facilities – For sterile, hygienic, and slip-resistant environments.

- Restaurants & Commercial Kitchens – Resistant to spills, grease, and heavy traffic.

- Industrial Plants & Warehouses – Withstands heavy machinery and chemical exposure.

- Schools & Universities – Durable enough for hallways, gyms, and labs.

- Retail Spaces – Provides both style and strength for customer-heavy environments.

- Residential Spaces – Used in garages, basements, and outdoor areas.

Installation Process of Epoxy Quartz Flooring

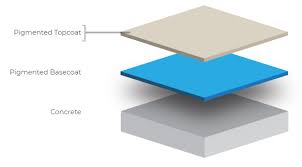

- Surface Preparation – Concrete is cleaned, repaired, and prepped for adhesion.

- Base Coat Application – Epoxy resin is applied to the prepared surface.

- Quartz Broadcast – Colored quartz granules are evenly spread across the surface.

- Intermediate Coat – Additional epoxy layers are applied for strength.

- Topcoat Sealing – A protective polyurethane or epoxy topcoat seals the system for durability and shine.

The result is a seamless, strong, and decorative floor that enhances both safety and aesthetics.

Why Choose an Epoxy Quartz System?

If you’re looking for flooring that offers strength, beauty, and long-term performance, the epoxy quartz system is an unbeatable solution. Its balance of functionality and design makes it one of the most popular choices across industries. Whether it’s for a commercial facility, an industrial plant, or even a stylish residential space, epoxy quartz flooring delivers value and reliability for years to come.